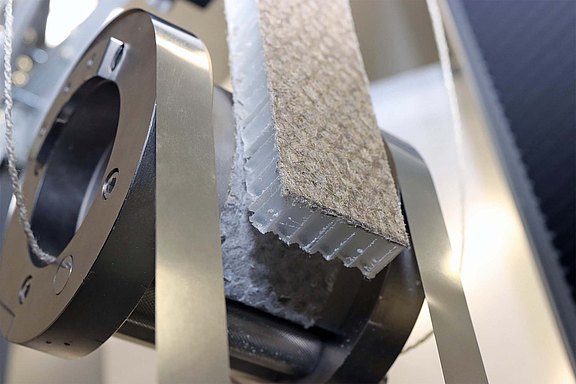

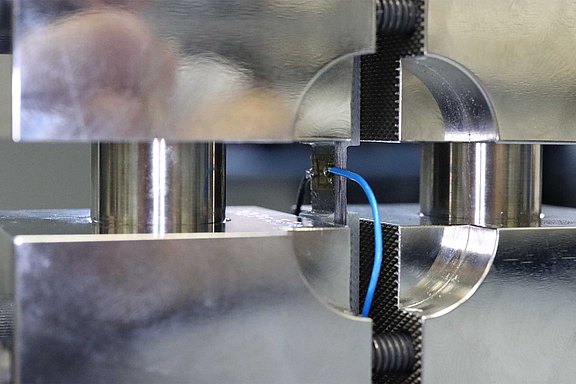

Plastics and composite testing is of great importance at TITK for accompanying research work on new materials and possible applications. In addition to the basic mechanical tests under quasi-static loads such as tensile, compression or flexure tests up to 250 kN load, dynamic tests such as impact or puncture tests can also be carried out. Standard grips as well as component-specific test setups are available for this purpose.

For comprehensive characterization, many test methods also offer the option of performing the tests in a range from - 50 °C up to temperatures of 150 °C. In addition to comprehensive mechanical characterization, tests on rheological or dynamic-mechanical material behavior are also possible in the laboratories.

In addition to standardized test methods, our staff can also set up and program application-specific test processes and sequences if required. For example, as part of method development, investigations are carried out into forming behavior in the pressing process, investigations for handling systems or even simulation of process sequences.