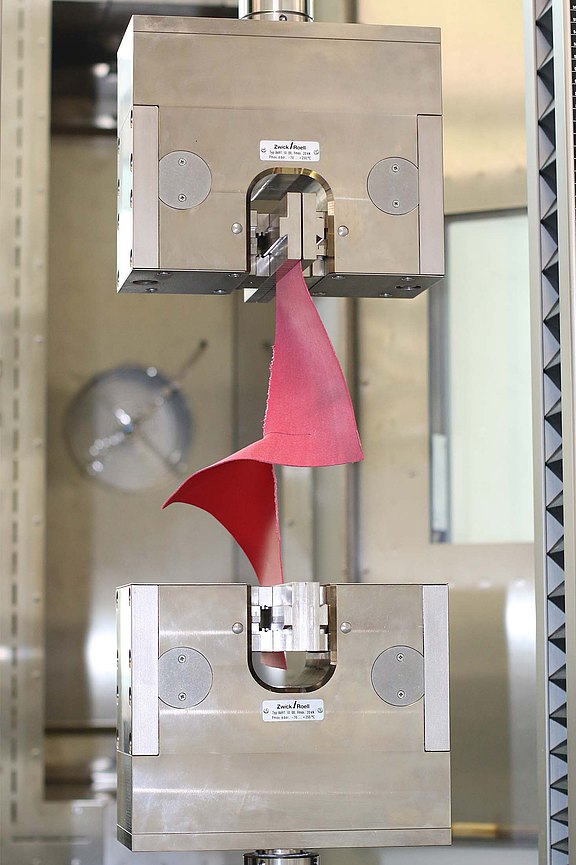

Textile parameters are of essential importance for developments in the field of technical textiles and fibre composites. In the TITK laboratories, extensive tests are carried out on individual fibres with regard to stiffness, strength or stress-strain behaviour under standard climatic conditions, and geometric parameters such as cross-section or fineness are determined using various test methods.

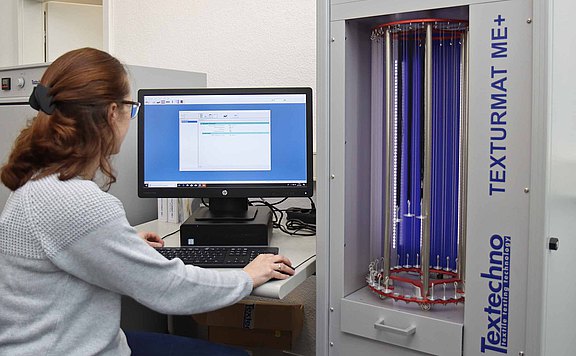

Semi-finished products such as rovings, yarns or textile surfaces (nonwovens, knitted fabrics, wovens or scrims) can also be characterised after further stages of textile processing. In addition to thermal stress and processing influences, extensive treatments are possible with regard to climate and weather resistance or the influence of media. Modern testing equipment and highly qualified personnel are available for this purpose.

In addition to standardised testing, application-specific or customer-specific test methods can also be developed to address various issues. These include methods for shrinkage characterisation or the shrinkage behaviour of textile semi-finished products for laying processes, methods for characterising processability and processing influences in production.