In the TITK's own developments, it was possible to demonstrate that the addition of conductive fibres can reduce the electrical resistance of elastomer compounds by several decimal powers. If these fibres can be oriented in a preferred direction, a product with anisotropic electrical properties is obtained - even during direct electrical heating. Deformations of such a material, especially in the direction of the fibre orientation, result in well measurable changes in the conductivity of the system.

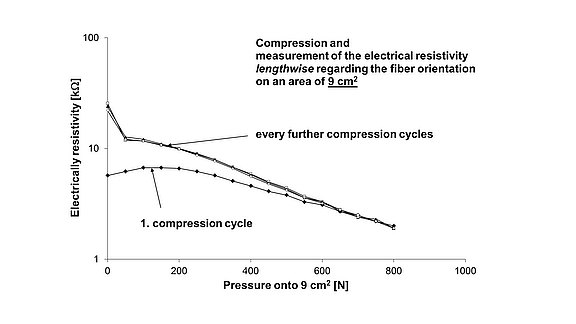

There are semi-quantitative correlations between the external pressure and the electrical resistance of such a rubber article. This relationship depends first of all on the elastomer itself (formulation and technological history). However, significant influences also result from the type, proportion, length, quantity and orientation of the conductive fibres. Soft fibres, such as conductive Lyocell, appear to be particularly suitable due to their low brittleness.

It could be proven in the TITK that measuring the pressure over a larger area with such a composite is possible in principle.