There is often the problem that in a fixed component the elastomer yields to external pressure (that it "flows"). This causes the system to fail over time. Taking the material into account, it is possible to contain this "flow" by increasing the hardness of the vulcanizate - i.e. either by high crosslinking or by increasing the filler content. With both approaches, however, it becomes difficult to harmonize all the necessary material parameters. In addition, even a stiffer elastomer component must still remain sufficiently flexible.

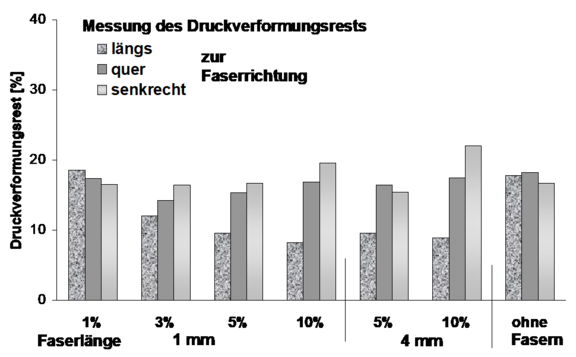

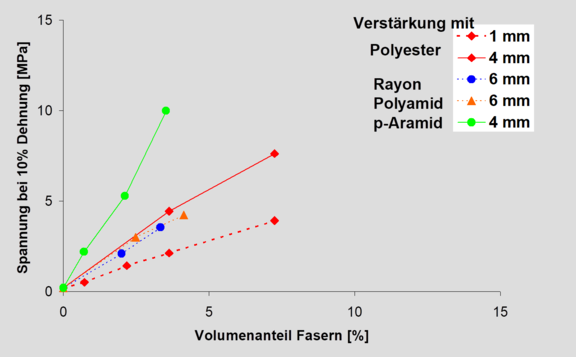

One way out of this is to fill the rubber with short fibers. Under certain conditions, the fibers in the elastomer compound can be oriented in a preferred direction. In this direction, the vulcanizate exhibits high stiffness, while flexibility is maintained perpendicular to it (anisotropy). Thereby, it is possible to anisotropically stiffen components (or their critical areas) with short fibers. This restricts "flow" in the problem zones without endangering the flexibility of the entire assembly in other directions. This can be demonstrated, for example, using a modified compression set test.

The difficulties with fiber reinforcement lie in the production and processing of elastomer compounds containing fibers. It is therefore necessary to adapt the fibers to the respective process. The rubber formulation as well as the entire technological spectrum in the processing of the elastomer compounds must also be optimized accordingly. Fundamental research work has been carried out on this at TITK.