In this area, the TITK is concerned with the optimization of existing manufacturing processes and procedures in order to make them more efficient, economical and sustainable. For example, TITK supports industry in the conversion from thermoset to thermoplastic composites, in the recycling and reuse of fiber composite materials, and in studies on weight reduction or functional integration.

The focus is on the following topics:

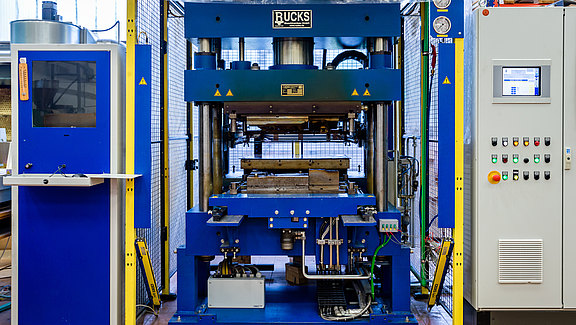

Pressing of thermoplastic and thermoset composites (on laboratory scale as well as up to a sheet size of 600 x 900 mm²)

- with RTM (Resin Transfer Molding) and SMC (Sheet Molding Compound) and wet press tools

- with an intermittent heating press (for high temperature resistant thermoplastics)

- Injection molding or back molding of fiber composites, scrims, films and various decorative material rails

- Direct processing of staple fibers (natural fibers, recycled carbon fibers, glass fibers)

- Thermoforming of thermoplastic films (e.g. for preparation/forming for subsequent back injection processes)

- Production of rotationally symmetric winding reels (dry and wet winding)

- Extrusion of sheets and profiles from fiber pellets with the possibility of partial reinforcement by continuous fibers

Many systems in the pilot plant are also designed for processing high-performance thermoplastics such as PPS, PEI or PEEK.

The development work starts on a small technical scale with low material input. Scaling up to industrial plant sizes is possible. Depending on the scope, it is also possible to produce initial samples and small series completely on the TITK systems.