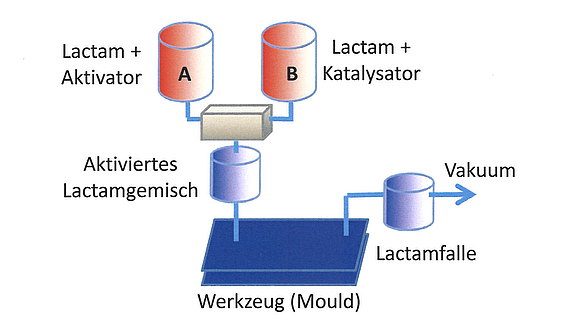

The anionic rapid polymerisation of lactam is based on a basic-initiated ring-opening polymerization and has the advantage of short polymerization times and low process temperatures of 150-160°C. High molecular weights and high strengths are achieved in the materials. The polymerization takes place in a mold in the geometry of the desired component, which can be removed from the mold after a short cooling phase. This allows, for example, the incorporation of reinforcing fabrics. Through vacuum infusion, an activated lactam mixture (e.g. ε-caprolactam) enters the mould in liquid form and can polymerise there. The process must be carried out under water-free conditions.

Polymerization parameters can be varied according to requirements. Concentration and type of catalyst/activator components in the mixture, polymerization rates, heat toning of the process and temperature control must be taken into account. In order to equip the materials with flame retardant properties or electrical conductivity, functional additives can be incorporated during polymerization with targeted and defined dispersion. Special attention is paid to sedimentation behavior and homogeneous distribution.

Technical equipment

- Dispermat up to 6500 rpm, evacuable and temperature-controllable stirrer vessel, extended stirrer

- Vacuum infusion test rig for the production of test samples of fabric-reinforced fiber composites by anionic rapid polymerization of lactams, cavity 260 x 200 mm with plate thicknesses of 2 mm and 4 mm

- Molds: heatable stainless steel mould, cavity 260 x 200 mm, insulated, incl. control/temperature control (up to 250°C), additional vibrator, evacuable

- Plate thicknesses through intermediate mold plates: 2 mm, 4 mm, 6 mm, 8 mm

- Sampling e.g. by means of CNC sample milling machine

- Material testing, e.g. thermal conductivity meter LFA 447

- Additive preparation by ball mill and spray dryer. e.g. production of nanoscale additives