The Department of Native Polymers and Chemical Research continues a long tradition for the production of man-made fiber materials. It originated from the R&D activities pursued by the Institute for Textile Technology of Man-Made Fibers (ITC) as the predecessor institute of TITK already since 1954, in which synthetic fiber materials and different generations of cellulose regenerated fiber materials were developed.

After the reestablishment of the institute as TITK, the department was mainly concerned with direct dissolution and dry-wet forming of functional & natural polymers, especially cellulose, other polysaccharides, proteins and polyacrylonitrile. The focus has been and still is on fiber developments as well as other forming processes for polymeric solutions. Extensive polymer and polymer solution characterization techniques are used as a basis for new developments.

An independently developed process for direct dissolution and dry-wet forming of cellulose and the special fibers obtained on its basis has been transferred to commercial scale. Process and product developments focus on cellulose, its chemical and physical modifications and deformation, as well as other soluble native and synthetic polymers.

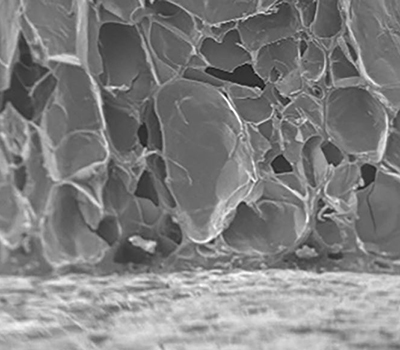

Since 2015, the department has also been conducting research activities in the field of adhesives and reactive foams. In addition to the development, characterization and modification of commercial adhesive systems and foams, the focus is also on bio-based and biodegradable alternatives.

With its chemists, process and textile engineers as well as physicists, the department has a long-standing tradition as a partner and service provider for the development of innovative fiber and other polymer moldings, adhesives and foams as well as the research-side co-design of processes or process parts.