In addition to injection moulding, extrusion, fibre spinning and film production, additive manufacturing of plastic parts is a research focus at TITK. Additive manufacturing (AM) - colloquially known as 3D printing - builds objects by depositing thin layers of molten plastic on top of each other layer by layer and then solidifying them.

Industrial 3D printing is used where individualised parts are needed in small quantities. The best-known examples are prototypes or implants in medicine. The printing of mould inserts enables the production of inexpensive small series in injection moulding machines. Multi-material systems enable the printing of functionalised components. For example, electrical conductors can be printed in three dimensions, fibres can be embedded to increase strength or objects with antibacterial surfaces can be generated.

Printing

Printing - in new labs with the following equipment:

- Stratasys Fortus 380mc

- F&B rapid production MetalBro 400 V2

- F&B rapid production Pro3digy

- Markforged Mark One

- Kühling&Kühling HT500 and many more

Laser scanning - certified measuring device Creaform Handyscan 300

Refinement - e.g. surface smoothing, metal vapour deposition, flocking (fur), increase of mechanical strength

Prototyping is supplemented by conventional machining processes, such as milling - a 5-axis DMG Mori DMU 50 milling machine is used here.

Measuring and Testing

- Determination of your optimal print settings (print speeds and nozzle temperatures,

- installation space and heating bed temperatures, bridging capacity)

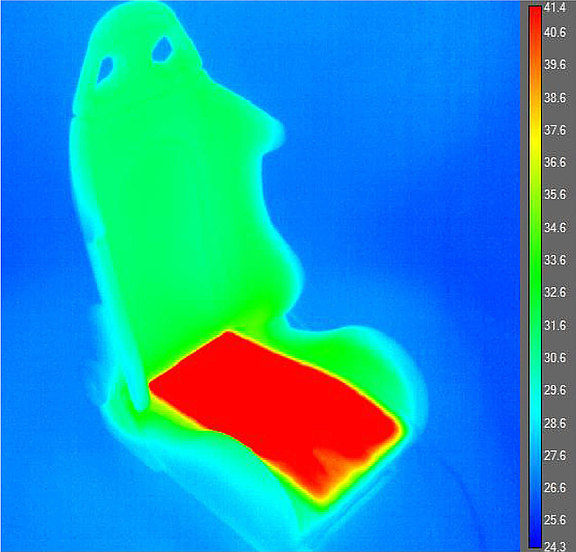

- Determination of your material properties (layer adhesion, warpage, heat resistance, impact and notched impact strength, fire protection class)

- Testing of your filaments (food contact approval EU10/2011, suitability for toys DIN EN71-3, suitability for drinking water KTW, flame retardancy DIN EN71-3, fire protection class)

- suitability KTW, flame retardancy, UL standards)

Research

The incorporation of active cooling functions, electrical conductors or continuous fibres is a competence of TITK, as is the post-treatment of additively manufactured parts. In addition to the process steps to increase mechanical strength, this includes smoothing the surfaces, flocking (fur) or vapour deposition with metals such as aluminium or gold.

The focus of research is on the FDM process. Among the current additive manufacturing processes, this method offers the greatest variety of materials at relatively low capital costs. The entire spectrum of thermoplastic materials from soft TPE to highly filled compounds to the high-temperature thermoplastic PEEK is processed.

To improve the processability of materials and to functionalise components, materials are chemically modified within a synthesis or mixed (compounded) in extruders. The mechanical strength and electrical conductivity within an applied layer differ from the values perpendicular to the layer. At TITK, research is being conducted into how materials must be modified and printing processes adapted so that components have uniform (isotropic) properties.