Task

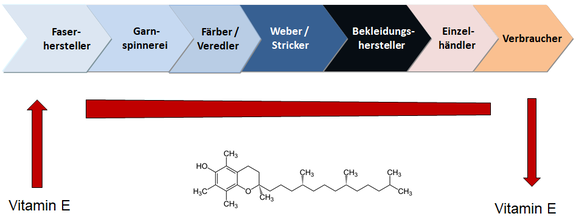

The aim of the project was to further develop a functional fibre that better meets the high demands of the textile industry in terms of processing and finishing throughout the entire textile chain (Figure). The research work included the identification and testing of new additives to reduce limiting factors. For the oleophilic phase, a wax was to be used that has a significantly lower vapour pressure but a higher polarity. For this purpose, the paraffin (octadecane) used so far was to be replaced by the fatty acid derivative Crodatherm 29 in order to minimise losses during the production of the fibres, during drying and further processing steps such as dyeing.

Results

The central focal points of the R&D work were the rheological adaptation of the oleophilic phase to form spinnable masses, the spinning of fibres and their further processing into yarns and fabrics. The criterion for all process steps was functional permanence, which was determined by an accompanying analysis of the heat storage capacity and the vitamin E content in fibres, yarns and fabrics. As a result of the R&D activities, a shear rate-dependent viscosity increase could be achieved. The influence of the layer silicates on the phase formation within the fibre was investigated. Preparation tests on the fibres led to the selection of a suitable lubricant for yarn production.

On a small-scale pilot plant, larger quantities of a thermoregulating and a vitamin E fibre could be produced under largely stable conditions. Both types had the theoretically expected functional content. However, the further process steps - yarn spinning, surface formation, dyeing, high-grade finishing - led to heavy losses of the function. Thus, the project goal of firmly integrating a wax with a lower vapour pressure could only be partially achieved.