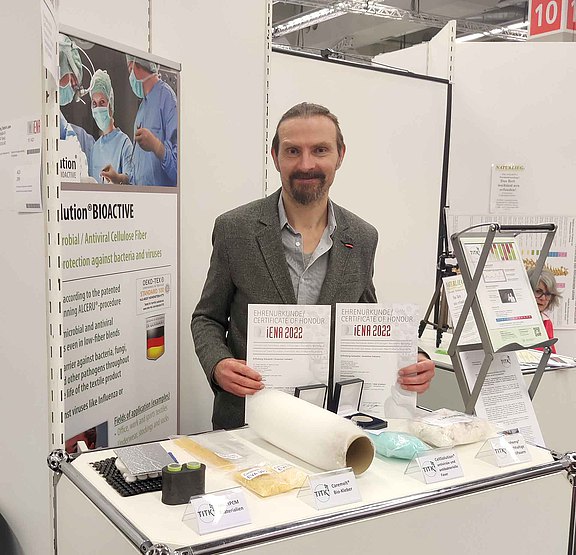

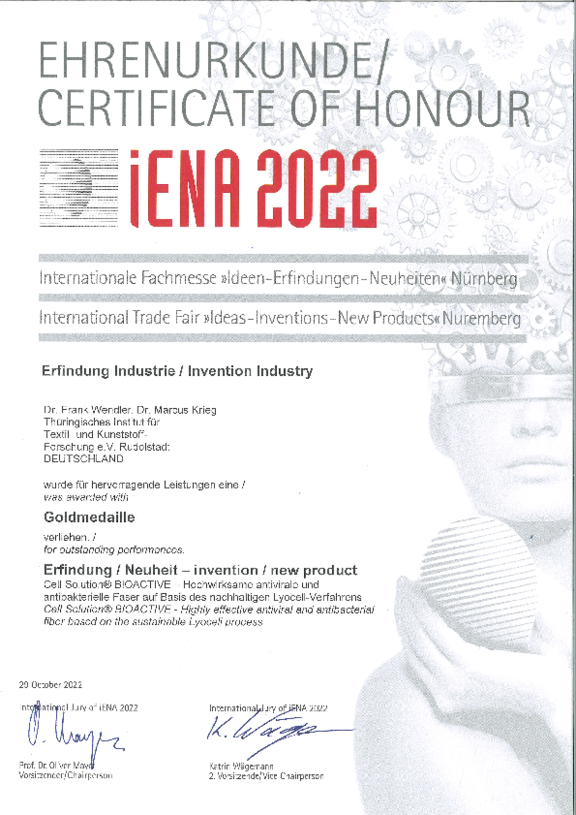

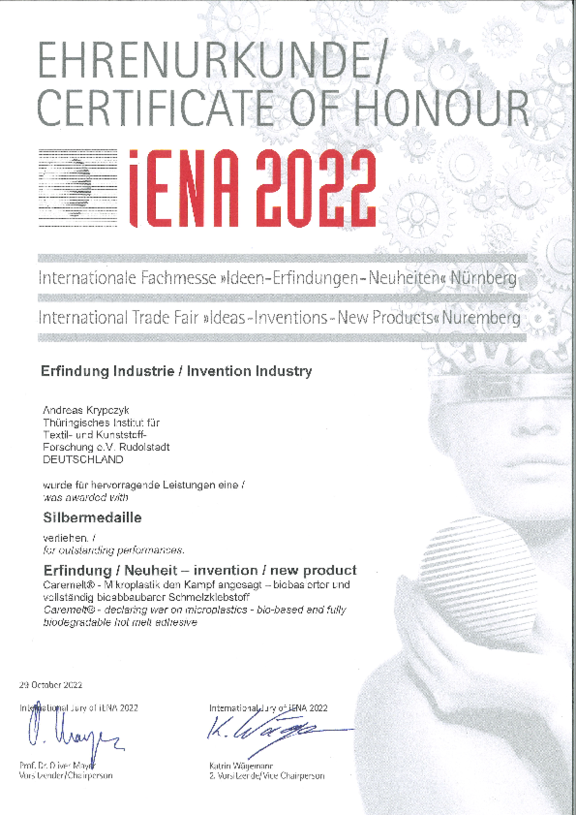

The antibacterial and antiviral cellulose fiber "Cell Solution® BIOACTIVE" and the completely biobased and biodegradable hotmelt adhesive Caremelt® have been awarded a gold and a silver medal at the International Inventors' Fair iENA in Nuremberg. The two highly sustainable materials were two of four innovations that the TITK - Thuringian Institute for Textile and Plastics Research e.V. exhibited in the Franconian metropolis from October 27 to 30.

Nuremberg – The last appearance of the TITK at the iENA Nuremberg - trade fair "Ideas, Inventions, New Products" - was already six years ago. In 2015 and 2016, the Rudolstadt research institute, which is close to the economy, was able to win several medals for its own developments in the field of sensor technology / polymer electronics. In 2022, the international jury now awarded gold and silver for two further promising innovations, which can be owed to the Native Polymers and Chemical Research department.

The gold-winning natural cellulose fiber "Cell Solution® BIOACTIVE" impressed with its antimicrobial properties. It reliably repels harmful bacteria and germs. And dangerous viruses, such as influenza or Covid-19, are killed after just 30 seconds of contact. The patented fiber is wash-resistant, so these properties are retained throughout the life of the textile product. As a positive side effect, unpleasant body odors are also eliminated.

Textiles with Cell Solution® BIOACTIVE can be used primarily in medical technology and are one of the most effective and natural agents in this field. Due to their moisture and temperature regulating effect, Cell Solution® fibers are generally gentle to the skin, which is confirmed by their listing with OekoTex®. By blocking bacterial growth, the bioactive version of the fiber also accelerates the healing process, especially of open wounds and neurodermatitis.

This year, the iENA jury honored the fully bio-based and biodegradable hotmelt adhesive Caremelt® with a silver medal. It is the first hotmelt adhesive to operate completely without fossil resources. Caremelt® thus offers industry the opportunity to make products that were previously not completely biodegradable because of their adhesive bonds completely sustainable.

Renewable raw materials such as plant starch from corn or potatoes, tree resins and plant waxes form the starting materials - in this case in the form of commercially available biobased plastics such as polylactides (PLA) and other additives such as biobased and harmless citric acid. The challenge here was to develop the right formulation for this so that Caremelt® could reach the level of conventional hotmelt adhesives. TITK succeeded in doing this by selecting the right raw materials and by additionally modifying the biopolymers.

The potential areas of application for Caremelt® are very diverse. They range from the packaging and furniture industries to the textile and automotive sectors. The use of biopolymers offers the advantage of CO2 neutrality on the one hand and residue-free biodegradability of the hotmelt adhesive on the other. Especially where recycling is neither technologically possible nor economically viable, this property becomes a decisive factor in reducing the input of microplastics into the environment.

The Caremelt® hotmelt adhesive had already won 2nd place in last year's Thuringian Environmental Award and is currently nominated for the Thuringian Innovation Award 2022 in the "Industry & Material" category.

TITK Managing Director Benjamin Redlingshöfer is happy to express his delight at the two new iENA medals: "A big thank you goes out to all the scientists involved in this." The awards once again recognize TITK's successful transfer efforts, Redlingshöfer said. "As a research institute with close ties to industry, we strive to make new materials available to industry quickly. And these two products are also already in the market launch phase."