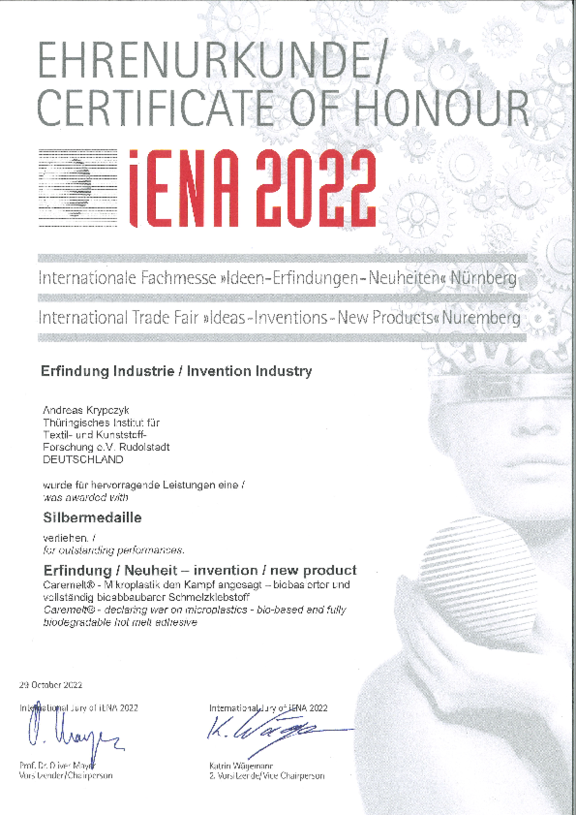

Caremelt stands for hotmelt adhesives based on biobased and/or biodegradable polymers. The polymers are partly modified chemically and/or by additives so that they can be used as base polymers for hotmelt adhesives. A selection of commercially available bioplastics is the basis for various types of caremelt.

These include:

- Polylactide (PLA)

- Polybutylene succinate (PBS)

- Polybutylene adipate terephthalate (PBAT)

- Polycaprolactone (PCL)

- Polyhydroxybutyrate (PHB)

For the formulation into ready-to-use hotmelt adhesives, additional natural resins as well as vegetable or animal waxes and plasticizers are used. Thus, formulations with different properties can be created in consultation with the customer.

After thorough testing, Caremelt has already been designated as a promising hotmelt adhesive by renowned adhesive manufacturers. The range of applications extends from the packaging industry to bookbinding and from the wood and furniture industry to the do-it-yourself sector. In addition to the classic application, however, hotmelt adhesives can also be modified in the form of films, nonwovens or powders for the textile and automotive sectors.