Functionalization of plastics for medical technology

Functionalization of plastics for medical technology

In the field of medical technology, TITK is researching the

- Markings for improved ultrasound and X-ray visibility

- Antibacterial and antiviral finishes for plastics

Ultrasonic and X-ray markings on medical devices

The markings for ultrasound and X-ray contrast are applied to plastic surfaces using laser technology in the form of patterns, inscriptions or graphics with high variability and very good imaging.

Antibacterial and antiviral finishes for plastics

One of our core topics continues to be the functionalization of polymer materials with antimicrobial and antiviral additives. Research activities include projects on antibacterial natural substances, antiviral coatings and biological agents such as antibacterial peptides and bacteriophages.

In addition to the development of materials for medical technology applications, biocopatibility tests in accordance with DIN EN ISO10993-5 can be carried out at TITK.

Technology Park

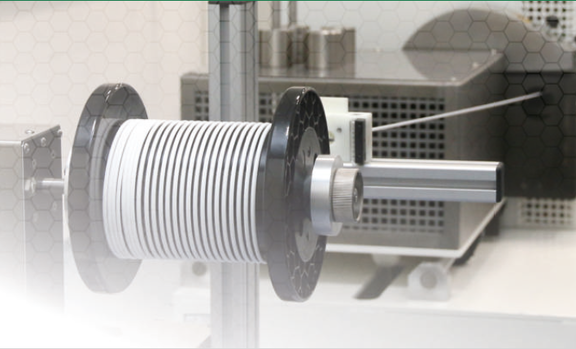

- Catheter extrusion systems for thermoplastics and silicone

- Extruders for compound and masterbatch production (ZSK 25 and 35)

- Injection molding systems (e.g. 2K, silicone)

- Film extrusion lines

- Coating

Current research topics in this area:

| Antithrombotic catheters through nanostructuring | Project manager | Dr. J. Bauer |

Laser-applied marks for medical instruments | Project manager | Holger Gunkel |

Echogenic marks on catheters through laser foaming | Project manager | Holger Gunkel |

Production of medical equipment with liquid-repellent plastic surfaces through laser structured injection molds. | Project manager | Holger Gunkel |

Antibacterial, bio-absorbable catheter coating | Project manager | Dr. J. Bauer |

Development of an antimicrobial cold polymerizing plastic to produce dentures with long-term effect to inhibit biofilm formation and reduce denture-induced, microbial inflammations | Project manager | Stefanie Griesheim |

Development of an innovative, antibacterial catheter based on biocompatible and environmentally harmless PVC substitutes | Project manager | Stefanie Griesheim |

| More information: | ||

| Flyer Plastics processing for medical technology |